Kanpur: Aligning with the government’s ambitious programme of being a self-reliant in ammunition manufacturing, Adani Defence and Aerospace has announced that it will be ramping the small calibre ammunition capacity to 300 million rounds in December this year, from existing 150 million rounds.

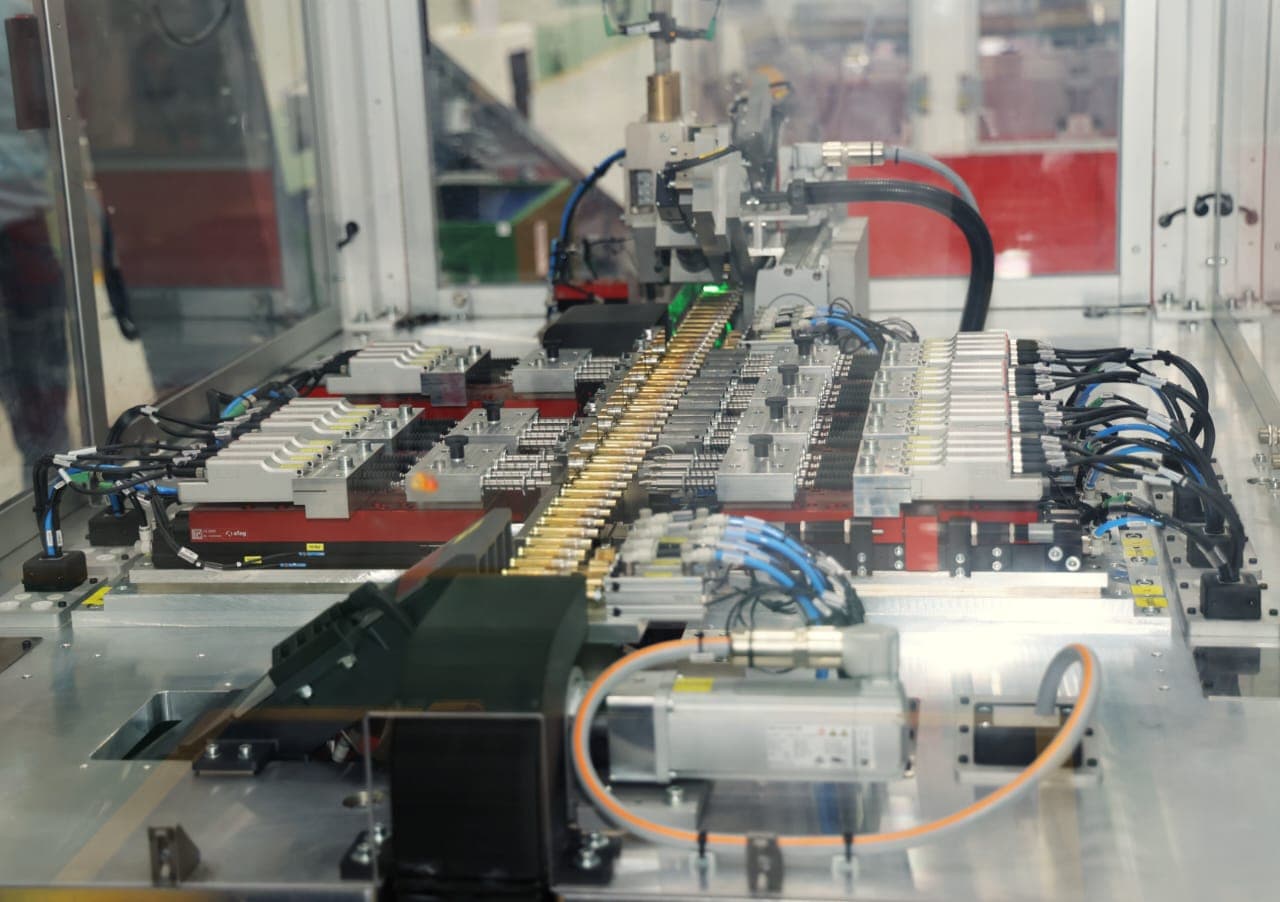

Besides, it is also in the process to scale the production of medium and large calibre cartridges and shells from the armed forces, central armed police forces (CAPFs) and state police. It should be mentioned that the small calibre ammunition is of 5.56 mm (used majority by Insas rifles), 7.62 mm (7.62x39 mm cartridge is used in the AK-47 and the newer AK-203 rifles, apart from 7.62x51mm NATO round is used in the Self-Loading Rifle (SLR) and the Machine Gun), .338 mm (sniper rifles) and 9mm (pistols). All these ammunitions are being produced at its fully-automated Kanpur facility spread across 500 acre in the UP Defence Corridor.

Speaking to visiting journalists, Adani Defence and Aerospace CEO Ashish Rajvanshi said: “This facility became operational in April 2024. We have transitioned from the commissioning phase to exporting in record time. By June 2024, just two months after the facility became fully operational, the company began shipping NATO-standard rounds, specifically 7.62×51 mm and 5.56×45 mm, to international clients.”

Rajvanshi also said that the company will be inaugurating a complex across the existing one in Kanpur to manufacture 150,000 large calibre ammunition rounds annually or 12,000 per month, the same as government owned Munitions India Limited did in the last 75 years. He further stated that Adani is also venturing into indigenising 125-mm anti-tank shells -- Armour-Piercing Fin-Stablished Discarding Sabot (APFSDS).

The defence ministry is pushing for indigenisation of Russian-origin APFSDS to overcome imports in munitions after getting transfer of technology from Moscow. So far close to 90 per cent of ammunition is being manufactured in India, most of it largely by the MIL. “The 125 mm anti-tank ammunition is one of the most important deficiencies in the Indian military inventories standing today and we are working towards that,” he said.

Likewise, the Adani is equally focussed on medium caliber ammunition, said Rajvanshi, to meet armed forces demand and supply gap. The medium caliber ammunition armed forces use include 20mm, 25mm, 30mm, and 40mm rounds. Infantry fighting vehicles, anti-aircraft artillery, and aircraft and naval guns use such ammunition.

“We are the first to work on setting up a facility in India in the same complex across 23, 30, and 40 mm by next Diwali,” he said while narrating the company’s expansion plan. On the orders received so far, he said that the company is already exporting ammunition to 4 countries and is supplying different category cartridges to armed forces, including 41,000 rounds of light machine guns to Indian Army, CAPFs and state police including to the UP.

Talking about Primer and Propellant, which are the major ingredients in ammunition manufacturing, he said India is one of the largest importers of them. “We will be setting up a manufacturing plant to get rid of import dependence from neighbouring country, the US, and Europe, on Primer,” -- a small explosive charge embedded within a cartridge case that ignites the gunpowder when struck by the weapon firing pin. And propellant are explosives.

On cost of bullets, he said that the company will help in bringing down the price. In 2019, the price per kg of propellant was less than $10 while it went up to $50 in 2025. The CEO further briefed that the Adani Group will also be setting up a 25,000 tons per annum capacity over the next two years. On indigenous content, he said: “The production line is nearly 100% indigenous, covering everything from brass strip processing to case manufacturing and final assembly.

“We start from the brass strip. The cup, the case, the bullet, everything is made in-house. The only component currently imported is the primer, which we plan to indigenise within the next two years fully,” he added.

You may also like

Emma Raducanu makes funny mistake after beating close friend in Canadian Open win

Lewis Capaldi's drummer left 'in floods of tears' after his Glastonbury comeback

Victorious Lionesses get the red carpet treatment at Downing Street after Euros heroics

'Heartbroken' Sharon Osbourne 'never alone' after Ozzy funeral plans spark concern

Ex-Arsenal star releases statement after being rushed to hospital with horror injury